Vacuum heat treat furnaces for a clean, efficient future

SECO/VACUUM, a SECO/WARWICK Group company, leads the heat treat industry with more new innovations than any other manufacturer, with an exclusive portfolio of all-vacuum technologies that are engineered to run clean and cool, operate more efficiently than legacy furnaces, produce cleaner parts, and reduce environmental impact by eliminating toxic emissions. Many of our vacuum furnaces are capable of performing Low Pressure Carburizing (LPC). Each of these products can help you upgrade and integrate your heat treatment operations with the manufacturing methods of the future.

Contact our SECO/VISORY team to discuss the best technology solution for your needs.

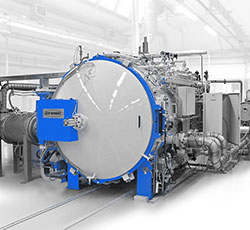

Vector® Single Chamber 2-25 Bar Gas Quench

For a wide range of heat treat processes, including LPC.

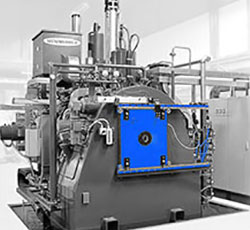

CaseMaster® Evolution: Multi-Chamber Oil Quench

For high-throughput

carburizing and LPC.

UniCase Master® Single-Piece Flow

Carburizing (LPC) and Low Distortion 4D Gas Quench

Gas Nitriding Furnace

For reliable, economical nitriding.

PIT LPC™ Furnace

Vacuum Carburizing Pit Furnace for Deep Case Depth on Large Parts

VT Series Vacuum Tempering Furnaces

For a wide range of heat treat processes, including LPC.

VAB

Vacuum Aluminum Brazing Furnaces

CVI-CVD Furnaces

Furnace for Chemical Vapor Infiltration (CVI) and Chemical Vapor Deposition (CVD)

Super IQ®: Gas Carburizing Furnace

The next generation Gas Carburizing Furnace.

Custom Vacuum Furnaces

Custom engineered systems to

support many process types.

Vacuum Furnaces

Vector®: Single Chamber, 2-25 Bar Gas Quench CaseMaster® Evolution: Multi-Chamber Vacuum Oil Quench 4D Quench Single-Piece Flow Gas Nitriding Furnace PIT-LPC™ Vacuum Carburizing Vacuum Tempering Furnace Vacuum Aluminum Brazing CVI/CVD Furnaces Super IQ®: Gas Carburizing Furnace Vacuum Furnaces for Sale

Specifications Subject to Change without Notice