First Choice Nitriding Furnace with ZeroFlow®

Single-chamber vacuum furnace with a proprietary process for regulated gas nitriding of machine parts, vehicles, aircraft, and tools.

Batch Gas-Nitriding Vacuum Furnaces

SECO/VACUUM offers gas nitriding furnaces in a variety of styles and models. The proprietary ZeroFlow® control technology uses only ammonia as a process gas thereby reducing gas usage and gas emissions.

SECO/VACUUM’s retort nitriding furnaces achieve optimum results by using uniform high convection heating, precision nitriding potential and ammonia control, along with vacuum purging to reduce operating costs to process a variety of metals.

Retort-based furnaces with vacuum purge for:

Retort-based furnaces with vacuum purge for:

- Gas Nitriding

- Ferritic Nitrocarburizing

- Post Oxidation (black)

- Stainless (activation) nitriding

- Nitrosulfurizing

- Tempering

- Annealing

Furnace Styles For Nitriding/NitroCarburizing

- Horizontal front-loading retort furnaces

- Vertical pit-style retort furnaces

- Electrically heated and natural gas heated designs (See more information on natural gas units in this video)

Request info or a quote on a ZeroFlow® Nitriding Furnace

Gas Nitriding Furnace Accessories

- Vacuum purge

- Turbo atmosphere cooler

- Simulation tools for layer control

Benefits of Nitriding with  ®

®

- Lower operating costs

- Attractive Return-on-Investment (ROI)

- Precise control of case depth

- Control of nitride layer formation (including white layer (compound zone))

- Two-stage nitriding process without additions of dissociated ammonia or nitrogen

- Simple ammonia-gas flow control

- Advanced process monitoring/control

- Low process gas consumption

- Reduced gas emissions (over alternative gas nitriding processes)

- In-situ process control

- Sophisticated process monitoring/recording and historical trending with a user-friendly HMI

- Remote monitoring and control (optional)

Industries Served and Typical Nitrided Parts

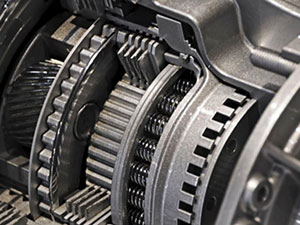

- Automotive, Racing, Heavy & Light Truck, Off -Road (gears, crankshafts, injectors, piston rods), Agriculture, General Industrial

- Aerospace, Aircraft, Rotocraft, Military and Defense (gears, pinions, actuators)

- Industrial Machinery & Goods (crankshafts, casting plates, locating pins, springs)

- Tool & Die (hot working dies, high-speed tool steel cutters)

- Corrosion resistance and Wear Resistance. Galling Resistance and added Lubricity.

Materials

- Low & Medium Alloy Steels (41xx, 43xx, 51xx, 86xx, 93xx series)

- Nitralloy® Alloys

- Stainless Steels (300 & 400 series, precipitation hardening grades)

- Tool Steels (H-series, M-series)

- Iron (ductile, gray)

Horizontal and vertical retort gas nitriding furnaces

Features

- Vacuum purge for removal of air from the retort and for removal of the nitriding atmosphere at the end of the cycle

- Automatic gas nitriding flow control for small or large loads

- Supervisory control system to continuously adjust and monitor process parameters

- Various grades of retort and internal alloys for long life (i.e. Inconel)

- Lowest ammonia consumption in the industry

- Burn-off stack to neutralize gas emissions from the system

- Low inert gas consumption (nitrogen or other process gases) for applications other than nitriding (annealing and tempering).

Standard models in red

| Horizontal Model # | Useful Dimensions in(mm) | Gross Load Weight lbs(kg) | Working Temperature °F(°C) | Temperature Uniformity °F(°C) | Number of Heating Zones | Furnace Heating Power (kW) |

|---|---|---|---|---|---|---|

| HRNe*-60.60.90-750-6-ZF | 24x24x36 (600x600x900) | 1320 (600) |

300-1380 (150-750) |

±5 | one | 75 |

| HRNe*-90.80.120-750-15-ZF HRNg**-90.80.120-750-15-ZF |

36x36x48 (900x900x1200) | 3300 (1500) |

300-1380 (150-750) |

±5 | three | 150 |

| HRNe*-100.100.150-750-25-ZF HRNg**-100.100.150-750-25-ZF |

40x40x60 (1000x1000x1500) | 5500 (2500) |

300-1380 (150-750) |

±5 | three | 240 |

*HRNe - Horizontal Retort Nitrider - Electrically Heated

**HRNg - Horizontal Retort Nitrider - Natural Gas Heated

Standard models in red

| Vertical Model # | Diameter in(mm) | Height in(mm) | Gross Load Weight lbs(kg) | Working Temperature °F(°C) | Temperature Uniformity °F(°C) | Number of Heating Zones | Furnace Heating Power (kW) | |

|---|---|---|---|---|---|---|---|---|

| VRNe-100.200-650-25-ZF | 39 (1000) |

78 (2000) |

5500 (2500) |

300-1200 (150-650) |

±5 | three | ||

| VRNe-120.300-650-50-ZF | 47 (1200) |

118 (3000) |

1100 (5000) |

300-1200 (150-650) |

±5 | three | ||

| VRNe*-60.90-650-6-ZF | 24 (600) |

36 (900) |

1320 (600) |

300-1300 (150-700) |

±5 | two | 40 | |

| VRNe-80.120-650-12-ZF | 32 (800) |

48 (1200) |

2645 (1200) |

300-1300 (150-700) |

±5 | two | 80 | |

| VRNe-100.150.650-30-ZF | 39 (1000) |

59 (1500) |

5500 (2500) |

300-1300 (150-700) |

±5 | two | 115 | |

| VRNe-120.150-650-30-ZF | 48 (1200) |

59 (1500) |

6600 (3000) |

300-1300 (150-700) |

±5 | two | 135 | |

| VRNe-140.250-650-45-ZF | 55 (1400) |

98 (2500) |

9900 (4500) |

300-1300 (150-700) |

±5 | three | 210 | |

| VRNe-160.250-650-60-ZF | 63 (1600) |

98 (2500) |

13200 (6000) |

300-1300 (150-700) |

±5 | three | 225 | |

*VRNe - Vertical Retort Nitrider - Electrically Heated

Vacuum Furnaces

Vector®: Single Chamber, 2-25 Bar Gas Quench CaseMaster® Evolution: Multi-Chamber Vacuum Oil Quench 4D Quench Single-Piece Flow Gas Nitriding Furnace PIT-LPC™ Vacuum Carburizing Vacuum Tempering Furnace Vacuum Aluminum Brazing CVI/CVD Furnaces Super IQ®: Gas Carburizing Furnace Vacuum Furnaces for Sale

Specifications Subject to Change without Notice

Resources

Brochure: Gas Nitriding Using the ZeroFlow® Process

Brochure: Gas Nitriding Using the ZeroFlow® Process Article: Nitrocarburizing for Automotive and Large-Volume Production

Article: Nitrocarburizing for Automotive and Large-Volume Production Video: Cambridge Heat Treating Puts ZeroFlow® Nitriding Process to the Test

Video: Cambridge Heat Treating Puts ZeroFlow® Nitriding Process to the Test

Case Study: Automaker Saves Money With High Volume Gas Nitriding/Ferritic Nitro-Carburizing System

Case Study: Automaker Saves Money With High Volume Gas Nitriding/Ferritic Nitro-Carburizing System Article: Gas Nitriding, A Short History

Article: Gas Nitriding, A Short History Webinar: Precision Nitriding

Webinar: Precision Nitriding