VT Series Vacuum Tempering Furnaces

Tempering is a process primarily used to increase the toughness of hardened ferrous-alloy parts. The tempering process is typically applied after a hardening process.

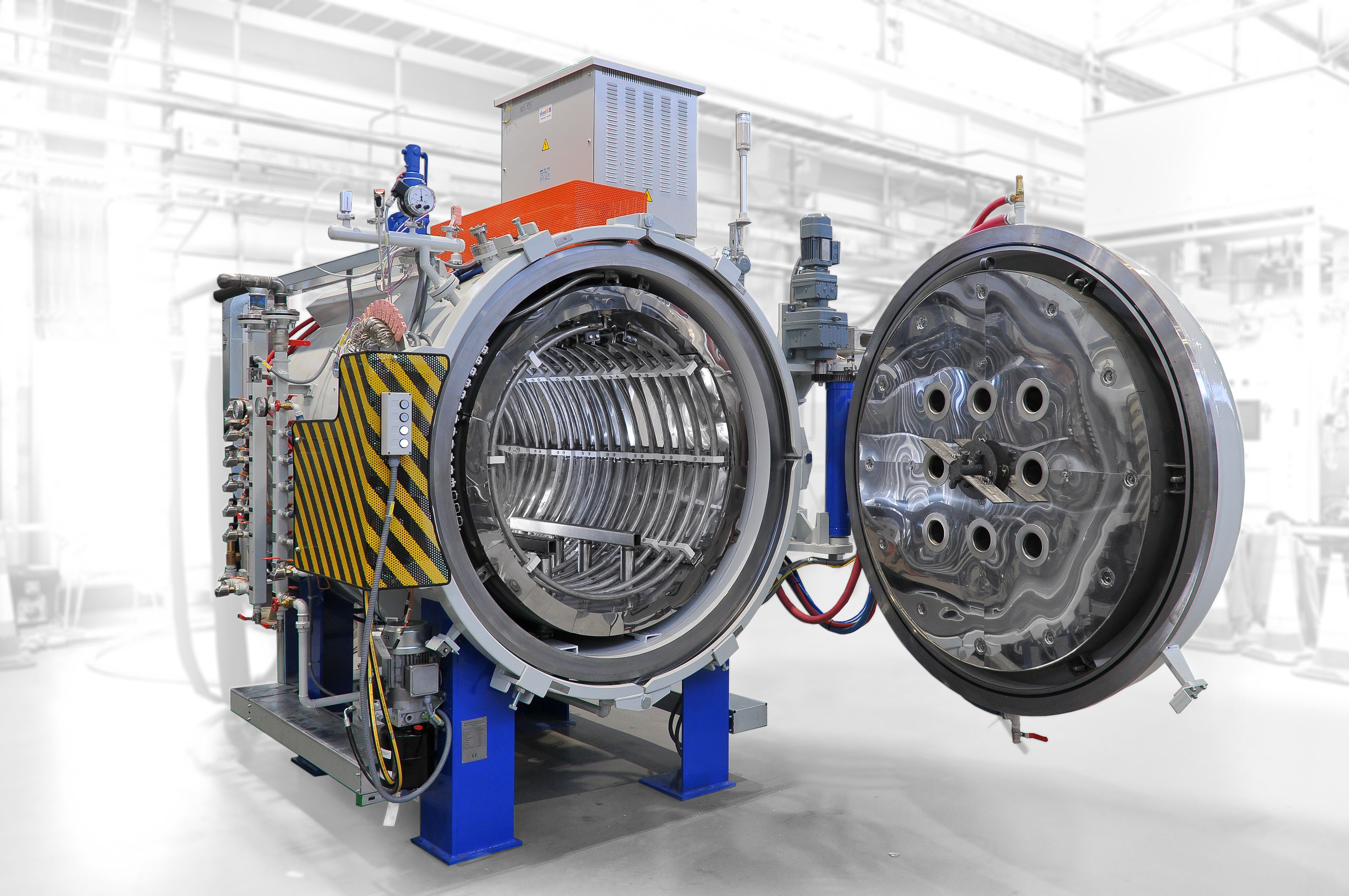

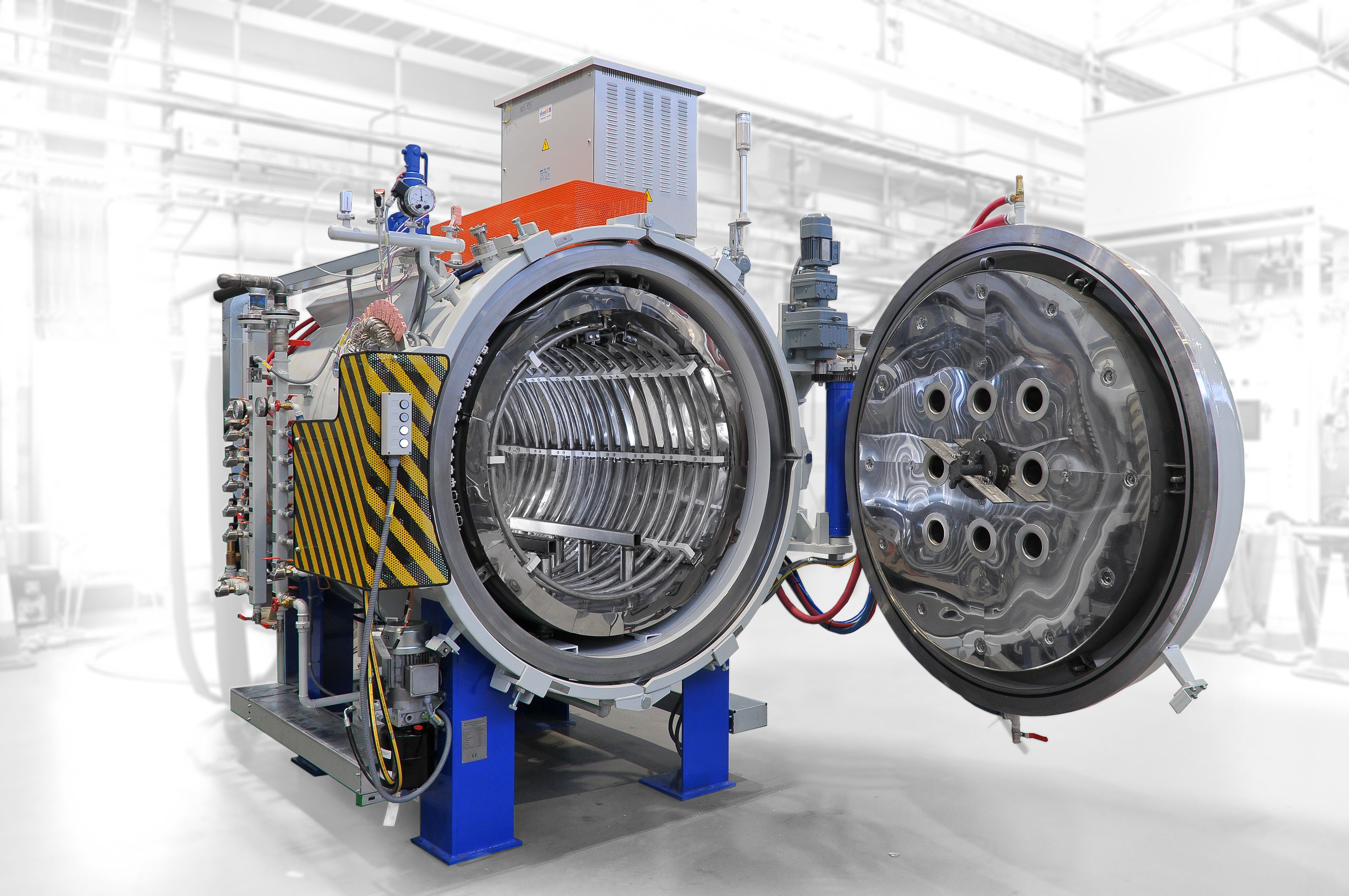

SECO/VACUUM’s VT series is an advanced cold-wall vacuum tempering furnace available in horizontal and vertical configurations.

The VT model’s compact design, with recirculation blower and heat exchanger configured to fit within the same footprint, requires minimum floor space. The vacuum tempering temperatures are achievable with furnaces capable of higher temperature vacuum heat-treating processes, but allocating those furnace resources for tempering is not always achieving optimal ROI. The tempering phase is often the bottleneck of a more comprehensive overall heat treatment. The VT furnace eliminates that bottleneck and frees up more advanced furnaces to spend more time on more advanced processes.

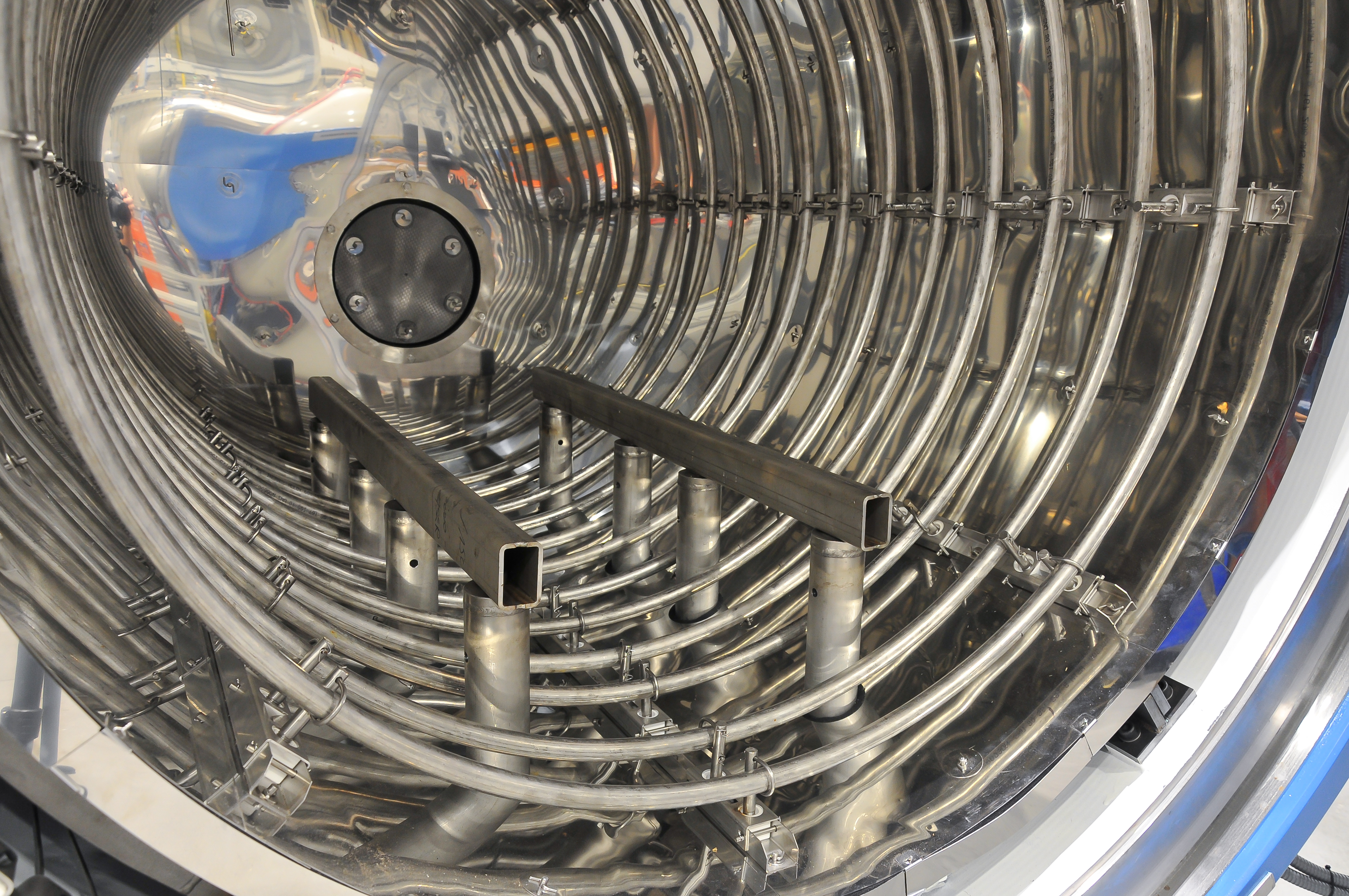

SECO/VACUUM’s line of Vacuum Tempering Furnaces is designed for quick and efficient vacuum tempering. Convection heating, gas cooling, and powerful vacuum pumping allow this tempering furnace to reach process temperatures and conditions and return to room temperature quickly, enabling smoother heat-treat process flow at an often-congested stage of the overall heat-treat process. Graphite felt insulation and metal heating elements provide long, reliable service in this heavy-duty furnace. The heating chamber design guarantees the best temperature uniformity within the working area.

Benefits

- Multiple heat treatment processes and applications

- Efficient use of space in Hot Zone accommodates oversized and unusually shaped parts

- Faster heat-up and cool-down times mean reduced process time

- Low consumption of energy, process gases and other utilities

- Environmentally friendly with low emissions of process gases

- Compact design, minimized floor space required

- Guaranteed quality and repeatable process results

- Predictive maintenance

- Remote control and monitoring

- Fast delivery and simple installation

- Customizable

Processes

- Tempering

- Low Temperature Annealing

- Degassing

Materials

- Tool steels

- Carburizing steels

- HSLA

- Alloyed steels

- Stainless steels

Industries

- Aviation

- Automotive

- Machine

- Tool

- Energy

- Medical

- Electronic

- Metallurgy

- Commercial heat treatment

- Specialty Applications

The VT is SECO/VACUUM’s most popular tempering model. It is a single chamber horizontal vacuum tempering furnace with a workload size that complies with industrial standards related to heat treatment equipment and has sold many hundreds of units worldwide. It comes with a full range of options and accessories for performing a wide range of functions for heat treaters and can be customized for special functions.

The furnace is completely assembled, leak tested, and then dismantled as required for shipment. The entire system will be ready for operation after re-assembly, interconnection of subsystems and connection to utilities in the PURCHASER’s plant, as required. Equipment manuals with operation and maintenance instructions, spare parts lists, and all necessary maintenance drawings will be provided.

Features

- Graphite Felt Thermal Insulation with Stainless Steel Screen Cover

- 1400F Operating Temperature (1650F Optional)

- Temperature Uniformity of +/- 5 10F

- 1.5 Bar Gas Cooling Pressure

- 10-1 to 10-2 torr vacuum operating range

- Uniformly distributed heating elements improve temperature uniformity

- Cylindrical heating chamber accommodates over-sized loads

- Load thermocouples port and control

SecoVac Automatic Furnace Control System

Maintenance and Control Features

- Functional, simple to use, intuitive system

- Uninterruptible Power System (UPS)

- Full visualization and comprehensive management of emergency situations

- Automatic generation of predefined reports (graphic or numeric) and with export to external files

- Hierarchy of user-access levels

- Remote control and monitoring

- Custom setup of all data analysis charts and printouts

- Full integration with SCADA software – no need of extra software

Production Features

- Friendly programming of the furnace system processes

- Advanced process management with unlimited number of recipes

Operation Features

- Operation time counters, ability to plan periodic reviews

- Controls available in multiple languages

- Stored history of equipment operation

- Power consumption monitoring

- Two-stage warning alarm – color coding allows immediate identification of alerts

- Easy system backups

Management Features

- Integration with higher-level management systems

- Data security with different levels of user’s access

- Optimization of production on the basis of stored information

- Reduced operator workload by automation of the production

- Long-term data logging and remote access to archived information

Models

| Style1 | Horizontal Configuration |

|||

|---|---|---|---|---|

| Model |

VT-446 |

VT-669 |

VT-9912 | |

Workload Size2: |

16 x 16 x 24 |

24 x 24 x 36 |

36 x 36 x 48 |

|

| Maximum Gross Load (lbs.) |

450 |

1300 |

3300 |

|

Notes:

- See product brochure for complete details.

- Custom sizes, special features and system configurations available

Dedicated Auxiliary Equipment

- Manual and/or automatic loaders

- Alloyed fixtures

- Closed loop water cooling system

- Gas buffer tank

- Noise protection of the pumping system

- Inlet gas dew point measuring system

- Temperature uniformity frame

- Time-saving spare parts set

Vacuum Furnaces

Vector®: Single Chamber, 2-25 Bar Gas Quench CaseMaster® Evolution: Multi-Chamber Vacuum Oil Quench 4D Quench Single-Piece Flow Gas Nitriding Furnace PIT-LPC™ Vacuum Carburizing Vacuum Tempering Furnace Vacuum Aluminum Brazing CVI/CVD Furnaces Super IQ®: Gas Carburizing Furnace Vacuum Furnaces for Sale

Specifications Subject to Change without Notice