SECO/VACUUM News

EV Manufacturer Purchases 2nd Retort furnace from SECO/WARWICK for electric car chassis production

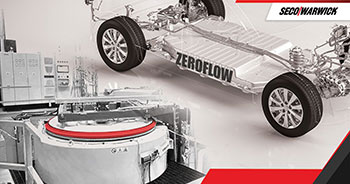

An international manufacturer of electric vehicles has placed an order with the SECO/WARWICK Group for an advanced retort furnace designed for nitriding using the ZeroFlow® method.

(Meadville PA, July 3, 2024)

(Meadville PA, July 3, 2024)The solution’s non-standard, larger working space will allow the nitriding of very large die elements needed to produce electric vehicle chassis. This is the second such furnace and the fourth SECO/WARWICK solution to be delivered to this Partner.

VR retort furnaces with a special design

The solution on order is an advanced retort pit furnace designed for nitriding using the ZeroFlow method, tempering, and annealing. The furnaces in this family have a compact design with vacuum purging, electric heating supported by an internal circulation fan and an external cooling system. The retort and heating system’s special design, as well as the gas installation, ensure long and reliable operation in industrial conditions.

The solution is based on a standard vertical VR retort furnace with an enlarged working space (Ø 1600 mm and 2800 mm effective height), allowing the Partner to nitride the huge dies used for electric car chassis.

“This is the fourth SECO/WARWICK furnace for this global manufacturer of electric vehicles. Our product solves the challenge of nitriding dies for producing large-sized chassis, using a working space with a diameter of 1,600 mm and a height of 2,800 mm. We delivered a similar solution to this Partner last year. At SECO/WARWICK, we focus on developing a product that meets our partner’s needs, which is why standard solutions have a number of modification possibilities and options. Thanks to this, customers receive a tailor-made product. We believe that an individual approach to each order is one of our greatest advantages in the metal heat treatment solutions market," said Maciej Korecki, Vice-President of the SECO/WARWICK Vacuum Segment.

ZeroFlow – precision and accuracy

The main advantage of ZeroFlow technology is its ability to conduct precise and fully controlled nitriding processes, which in turn produce high accuracy of the nitrogen layers obtained with the lowest possible ammonia consumption.

“We have designed a solution with dimensions enabling the nitriding of large, heavy parts in a way that meets the customer’s specifications. The patented ZeroFlow® controlled nitriding process allows users to obtain optimal results while consuming even several times less ammonia compared to traditional nitriding, which is beneficial both in economic and ecological terms,” commented Jędrzej Malinowski, Sales Manager of the SECO/WARWICK Vacuum Furnace Segment.

The atmosphere circulation system installed in the furnace directs the atmosphere flow along the retort walls and through the load. This ensures appropriate temperature distribution during heat treatment. ZeroFlow is a modern version of controlled gas nitriding that maximizes the process effectiveness and efficiency, as well as the economic output, significantly exceeding the results of traditional solutions. It allows for the precise shaping of any nitrided layer composition while maintaining minimal factor consumption and post-process gas emissions, meeting the most stringent environmental protection regulations.