SECO/VACUUM News

Industrial automation manufacturer offers in-house hardening capabilities with SECO/WARWICK technology

An international organization in the field of industrial automation has ordered a SECO/WARWICK heat treatment system with the goal of establishing a captive hardening plant within their machine park. This comprehensive technological line for hardening applications will consist of two Vector® vacuum furnaces, an atmosphere furnace, and a washer.

(Meadville PA, February 22, 2023)

(Meadville PA, February 22, 2023)This is another SECO/WARWICK installation enabling partners to expand their production capacity with an in-house hardening plant. This is another partner that has trusted the Group’s experience in the comprehensive execution of in-house hardening plants. Clients have discovered that adding a captive hardening heat treatment manufacturing system is an ideal solution because it gives companies independence from relying on external service providers. This investment is also a guarantee of timeliness as well as high-quality of heat treatment processes.

The furnaces on order will be used for hardening and vacuum carburizing the elements used in motor reducer production. These parts are used in the production process for automation applications in industries such as automotive, aviation, food and printing.

An in-house hardening plant means independence

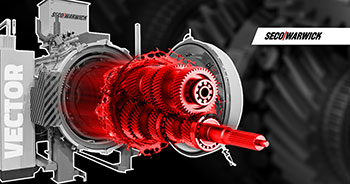

The line of furnaces on order for vacuum carburizing will be equipped with the signature SECO/WARWICK FineCarb® technology and HPGQ high-pressure gas quenching. The system will include two Vector compact vacuum furnaces, which are the model for all of the solutions of this type worldwide. Their unwavering reputation is demonstrated by the fact that these furnaces work in over 70 countries, implementing heat treatment processes for the most important industries. In combination with a washer and an additional tempering furnace, they provide comprehensive heat treatment, starting with the wash cycle, through carburizing, hardening, and tempering. The furnace’s compact size will ensure the appropriate flexibility and efficiency required by the Partner, due to the wide range of machined details in complex work such as gears, shafts, and pinions.

“In these times of constant problems with maintaining the supply chain, having captive heat treatment within a machine park provides our partners with a huge competitive advantage and independence. Within a relatively small area, we can create a heat treatment system that will meet the Partner’s needs. Such an investment of this type pays off very quickly, as evidenced by the growing orders for our partnership in building in-house hardening plants,” says Maciej Korecki, Vice President of the Vacuum Furnaces Segment at SECO/WARWICK Group.

A small hardening plant for big needs

The situation in global markets after the Covid-19 pandemic causes a constant problem with strategic material acquisition and tool processing in production companies. The price for the freedom of hardening plant ownership from high transportation costs and delivery delays is not that high when compared to the alternative. A small internal hardening plant consisting of two Vector vacuum furnaces, an atmosphere furnace and a washer ensures complete independence from commercial service providers.

“We have solved the Partner’s problem related to maintaining the continuity of production. This project was mainly concerned with the production process of gears, shafts, and pinions. Delays disrupt the continuity of the entire production chain. Our furnaces give the manufacturer independence and flexibility, the value of which cannot be overestimated nowadays. Thanks to this upgrade in capacity, they gain full control over the thermally treated element quality, adding the convenience of flexible production, even for short runs, and can additionally reduce the risk of production delays. Ownership of the hardening plant is a development investment which will introduce a new production order. At the same time, it provides significant savings in terms of costs related to transportation; given the current fuel prices, this is a significant cost item,” explains M. Korecki.

Vector – the ideal design is unique in the industry

The vacuum furnaces on order are solutions with compact dimensions which will meet the customer’s requirements for hardening and carburizing parts, specifically gears, pinions, and shafts. It is a standard, proven design that stands out for its reliability.

The characteristic features of these furnaces are a round heating chamber with excellent temperature uniformity, +/-5oC, convection heating and isothermal hardening. Vectors guarantee the execution of precise, high-quality carburizing processes. As a standard, they are equipped with an efficient and ergonomic pumping system, as well as an effective cooling system. All this makes these furnaces one of the most popular vacuum solutions in the world.