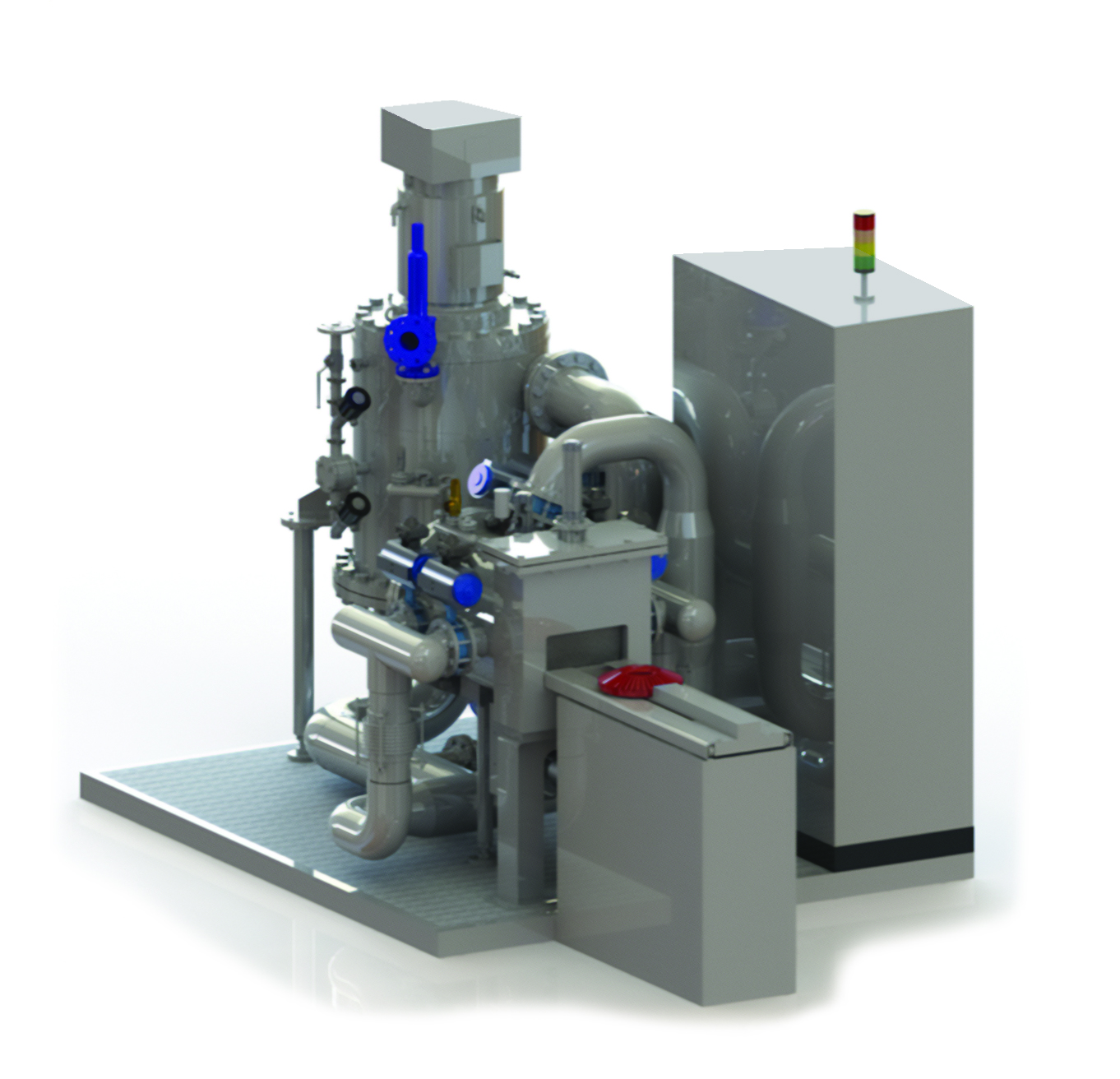

UniCase Master® Solo 4D Quench® Module

UniCase Master® Solo 4D Quench® Module

The Modern Alternative to a Quench Press

What is 4D quenching? The 4D Quench is a modern alternative to a quench press. 4D quenching is a vacuum heat treatment solution for single piece quenching with distortion control and reduction. The SECO/WARWICK 4D Quench enables customers to replace oil quenching with a clean environmentally friendly, cost-effective nitrogen quenching technology. The 4D Quench provides a distortion-free alternative to oil and quench presses and the problems associated with their operation.

Replaces a standalone press quench following atmosphere carburizing or austenitizing.

SECO/VAC’s 4D Quench provides distortion control and is a modern solution to press quenching while eliminating a number of the challenges linked to their operation.

Benefits

- Improved quenching with precise control and minimization of distortion.

- The quenching process can be engineered prior to manufacturing as the cooling nozzles can be arranged in a specific arrangement to attain the optimal gas quenching profile on a part, while utilizing nitrogen or clean dry compressed air; outcomes are equal to that of press quenching.

- Introducing a green machined component and extracting a freshly hardened component, the 4D Quench system processes materials in a continuous flow for seamless production.

Features

- Equipment can be installed and is operable adjacent to current heat treating equipment on the manufacturing floor.

- 4D Quench system is equipped with a rotary load table that provides precise rotation control and speed.

- The touchscreen control interface is simple, user-friendly and intuitive to use.

Vacuum Furnaces

Vector®: Single Chamber, 2-25 Bar Gas Quench CaseMaster® Evolution: Multi-Chamber Vacuum Oil Quench 4D Quench Single-Piece Flow

- Solo 4D Quench

- Reheat +4D Quench Furnace

- HiFlow LPC +4D Quench Furnace

- Multistage +4D Quench Furnace

Specifications Subject to Change without Notice

Brochure: UniCase Master

Brochure: UniCase Master Video: 4D Quench

Video: 4D Quench